Luggage Security System

Two Basic Motor Speed Controllers

Here a quad NOR gate (IC1) acts as a 50Hz astable multivibrator that generates a rectangular output. The mark-space ratio of the rectangular waveform is fully variable from 20:1 to 1:20 via potentiometer VR1. The output from the multivibrator drives the base of Q1, which in turn drives Q2 and the motor. The motor’s mean supply voltage (integrated over a 50Hz period) is thus fully variable with VR1 but is applied in the form of high-energy "pulses" with peak values of about 12V.

This type of circuit gives excellent full-range speed control and gives high motor torque, even at very low speeds. Its degree of speed self-regulation is proportional to the mean value of the applied voltage. Note that for most applications, the power transistor (Q2) in both circuits will need to be mounted on an appropriate heatsink.

Alarm Clock With Day Selector

This circuit disables an alarm clock on Saturdays and Sundays when people like to sleep in but enables normal operation on Mondays to Fridays so that people rise in time for work or school. The core of the circuit is a 4017 decade counter which acts as the day counter and it is used in conjunction with a desk clock which acts the alarm and a watch module with alarm function which provides one clock pulse very day to the 4017. In operation, the watch module feeds a day pulse via transistor Q3 to the clock input of IC1. This has seven outputs connected via day switches (S1-S7) and diodes D3-D9 to Q1 which disables the alarm signal to the speaker via transistor Q2. LEDs1-7 indicate the actual day (if you forget!).

Circuit diagram:

Alarm Clock With Day Selector Circuit Diagram

To set the system, set the desk clock for the correct time and for the desired alarm time (eg, 6’o’clock). The watch module is set to the correct time and its alarm set to midnight. The day counter, IC1, is set to the correct day, as indicated by the LEDs, by pushing switch S12 and closing switch S8 or S9. S8 is normally left open to conserve the battery by leaving the LEDs off. As shown on the circuit, switches S1-S7 are set to sound the alarm on Mondays to Fridays and disable it on Saturday and Sunday. However, you can change the days to suit your work habits.

Author: Rasim Kucalovic - Copyright: Silicon Chip Electronics

Park Aid Modification Circuit

Three-step beeps signal bumper-barrier distance, Infra-red operation, indoor use

This modification was designed on request: some people prefer an audible alert instead of looking at the LED display, making easier the parking operation. The original Park-aid circuit was retained, but please note that the input pins of IC2B, IC2C and IC2D are reversed. LEDs D5, D6 and D7, as also resistors R12, R13 and R14 are omitted. IC2B, IC2C and IC2D outputs drive resistors R15, R16 and R17 through D8, D9 and D10 respectively, in order to change the time constant of a low frequency oscillator based on the 555 timer IC4. This allows the Piezo sounder to start beeping at about 2 times per second when bumper-wall distance is about 20 cm., then to increase the beeps to about 3 per second when bumper-wall distance is about 10 cm. and finally to increase further the beeps frequency to more than 4 beeps per second when the distance is about 6 cm. or less.

Circuit diagram:

Park-Aid Modification Circuit Diagram

Parts:

R15_____________3K3 1/4W Resistor

R16___________330K 1/4W Resistor

R17___________470K 1/4W Resistor

R18___________150K 1/4W Resistor

C6______________1µF 63V Electrolytic or Polyester Capacitor

D8,D9,D10____1N4148 75V 150mA Diodes

IC4_____________555 Timer IC

BZ1___________Piezo sounder (incorporating 3KHz oscillator)

Source : www.redcircuits.com

555 Timer With Variable On Off Times

Therefore the capacitor at pins 2 & 6 is charged via diode D2 and trimpot VR2 and discharged via D1 and trimpot VR1. With this arrangement you can have very long on times combined with very short off times and vice versa, or you can adjust the duty cycle to exactly 50% and so on. This circuit also employs a second 555 timer (IC2) as an inverter so that complementary pulses are available, if required. If not, delete IC2.

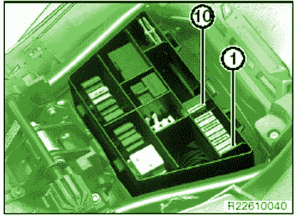

Fuse Box BMW R1150RT 2002 Diagram

Fuse Box BMW R1150RT 2002 Diagram

Fuse Panel Layout Diagram Parts: instrument cluster, telltale light, revolution counter, indicator clamping, windscreen adjuster, parking light, tail light, windscreen adjuster, power socket, radio, horn, motronic control unit, motronic relay, diagnosis connector, fuel pump relay, oxygen sensor, heated handlebar grips, radio, fog lamp relay.

Build a 16 LED Chaser Circuit Diagram

16 LED Chaser Circuit Diagram

When the D16 lit the situation changes and there is a reverse movement. Lit D15-14 ……D16, is lit making circles when the circuit is under power. The IC1 is an unstable flip- flop supplying with stable frequency pulses (the frequency can be changed by TR1, adjusting the velocity of the LEDs up and down).

This frequency supplies the IC3 (which is a 4-Bit UP and DOWN counter) through 2 gates A-B of the IC2. The output counter supplies the IC4 that is the driver of the LEDs. The parts C- D of The IC2, make a R-S flip- flop, that changes situation, when the edge LEDs D1 and D16 lit.

We have an electronic limit for the situation change. In proportion the shape we make with the LEDs, we can have the proportionate optional result, making various effects.

Part List

R1= 100Kohms

R2= 220Kohms

R3= 470 ohms

TR1= 1Mohms

C1= 330nF 100V MKT

D1-16= LED 5mm

IC1= 555

IC2= 7400

IC3= 74193

IC4= 74154

3 Transistor Audio Amplifier Circuit

Circuit Source - http://www.electronguide.com/circuits_pages/3_Transistor_Audio_Amp.html

Mobile Cellphone Battery Charger Circuit

Parts

- P1 = 20K

- P2 = 20K

- R1 = 390R

- R2 = 680R

- R3 = 39R-1W

- R4 = 27K

- R5 = 47K

- R6 = 3.3K

- R7 = 100R-1W

- C1 = 4.7uF-25V

- C2 = 0.01uF

- C3 = 0.001uF

- D1 = 5.6V-1W Zener

- D2 = 3mm. Red LED

- Q1 = SL100

- S1 = On/Off Switch

- B1 = 1.5vx8 AA Cells in Series

- IC1 = NE555 Timer IC